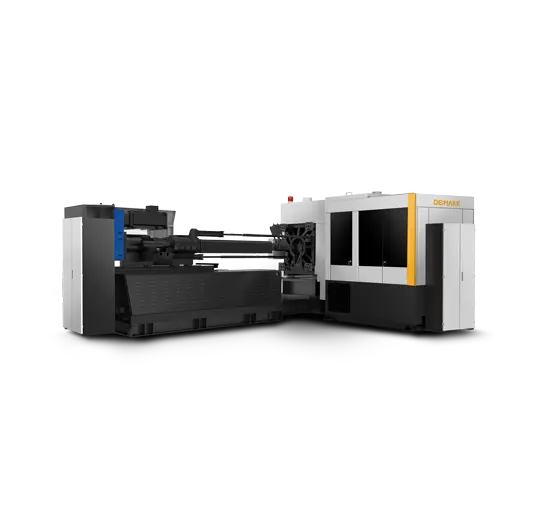

iPET PET Preform Injection Molding System

● For 72, 96 Cavities PET Preform Molds

● Cycle: 8S/14g/72cav.

● Two-Step Injection, 5 sets of high efficient accumulator

● With 3 Station Cooling Robot, Electric Plasticization

- 1 Independent electric screw drive brings you both melting and energy efficiency

- 2 BECKHOFF centralized control system special designed for PET production.

- 3 Three station post cooling robot makes the preform perfectly cooled with better cycle time.

- 4 Advanced servo valve control technology makes the highly dynamic injection possible.

- 5 Up to 5 sets of high efficient accumulator ensure the stability of high capacity injection .

- 6 Synchronous material melting,plasticization and injection at the same.

- 7 Special design for PET preform mould,which ensure the fast clamping movement and uniformly forced of the mould.

| Model | UNIT | iPET300/3500 | iPET300/5000 | iPET400/5000 | iPET400/6000 | iPET500/7000 | |

| INJECTION UNIT | Screw L/D Ratio | L/D | 25 | 25 | 25 | 25 | 25 |

| Screw Diameter | MM | 100 | 120 | 120 | 130 | 140 | |

| Shot Weight(PET) | G | 3500 | 5000 | 5000 | 6200 | 7200 | |

| Plasticizing Rate (PET) | G/S | 200 | 300 | 300 | 380 | 470 | |

| CLAMPING UNIT | Clamping Force | T | 300 | 300 | 400 | 400 | 500 |

| Clamping Stroke | MM | 585 | 585 | 670 | 500 | 550 | |

| Max/Min Thickness of Mould | MM | 300~720 | 300~720 | 300~820 | 500~1300 | 550~1350 | |

| Space Between Tie Bars(WxH) | MM | 660x760 | 660x760 | 845x845 | 920x920 | 1020x1120 | |

| Ejector Stroke | MM | 180 | 180 | 180 | 200 | 200 | |

| Ejector Force | T | 20 | 20 | 28 | 41 | 51 | |

| NO.of Ejector Pins | PCS | 9 | 9 | 13 | 10 | 10 | |

| MOULD | Cavity(Max) | PCS | 72 | 72 | 96 | 128 | 144 |

| Type of Mould | Needle Valve Of Non-cutting PET Preform Mold | ||||||

| POWER UNIT | Pump Motor Power | KW | 81+82 | 81+82 | 81+82 | 110+130 | 130+130 |

| Robot Power | KW | 36 | 36 | 43 | 108 | 108 | |

| Heater Input Capacity | KW | 78 | 86 | 86 | 130 | 130 | |

| Mould Heater Capacity | KW | 55 | 55 | 68 | 90 | 90 | |

| ROBOT | Manipulator | Cavity | 216 | 216 | 288 | 384 | 432 |

| Cooling Form | Cavity | 216 | 216 | 288 | 384 | 432 | |

| Size(LxWxH) | CM | 263X157X230 | 263X157X230 | 281X160X250 | 315X260X273 | 315X260X273 | |

| OTHER | Power supply (3-phase AC) | V/HZ | 380/50 | 380/50 | 380/50 | 380/50 | 380/50 |

| KW | 332 | 332 | 360 | 568 | 568 | ||

| Chilling Water | ℃ | 5~10 | 5~10 | 5~10 | 7~9 | 7~9 | |

| Mpa | 0.8 | 0.8 | 0.8 | 0.8 | 0.8 | ||

| L/Min | 900 | 900 | 1200 | 1200 | 1200 | ||

| Cooling Water | ℃ | <25 | <25 | <25 | <25 | <25 | |

| Mpa | 0.3 | 0.3 | 0.3 | 0.3 | 0.3 | ||

| L/Min | 300 | 300 | 300 | 300 | 300 | ||

| Compressed Air | Mpa | 0.7~0.9 | 0.7~0.9 | 0.7~0.9 | 0.7~0.9 | 0.7~0.9 | |

| L/Min | 800 | 800 | 1200 | 1200 | 1200 | ||

| Machine Size(LxWxH) | CM | 930X180X250 | 990X180X250 | 1090X205X260 | 1180x250X270 | 1240X270X300 | |

| Machine Weight | T | 26 | 28 | 34 | 39 | 44 | |

| Model | UNIT | iPET300/3500 | iPET300/5000 | iPET400/5000 | iPET400/6000 | iPET500/7000 | |

| INJECTION UNIT | Screw L/D Ratio | L/D | 25 | 25 | 25 | 25 | 25 |

| Screw Diameter | MM | 100 | 120 | 120 | 130 | 140 | |

| Shot Weight(PET) | G | 3500 | 5000 | 5000 | 6200 | 7200 | |

| Plasticizing Rate (PET) | G/S | 200 | 300 | 300 | 380 | 470 | |

| CLAMPING UNIT | Clamping Force | T | 300 | 300 | 400 | 400 | 500 |

| Clamping Stroke | MM | 585 | 585 | 670 | 500 | 550 | |

| Max/Min Thickness of Mould | MM | 300~720 | 300~720 | 300~820 | 500~1300 | 550~1350 | |

| Space Between Tie Bars(WxH) | MM | 660x760 | 660x760 | 845x845 | 920x920 | 1020x1120 | |

| Ejector Stroke | MM | 180 | 180 | 180 | 200 | 200 | |

| Ejector Force | T | 20 | 20 | 28 | 41 | 51 | |

| NO.of Ejector Pins | PCS | 9 | 9 | 13 | 10 | 10 | |

| MOULD | Cavity(Max) | PCS | 72 | 72 | 96 | 128 | 144 |

| Type of Mould | Needle Valve Of Non-cutting PET Preform Mold | ||||||

| POWER UNIT | Pump Motor Power | KW | 81+82 | 81+82 | 81+82 | 110+130 | 130+130 |

| Robot Power | KW | 36 | 36 | 43 | 108 | 108 | |

| Heater Input Capacity | KW | 78 | 86 | 86 | 130 | 130 | |

| Mould Heater Capacity | KW | 55 | 55 | 68 | 90 | 90 | |

| ROBOT | Manipulator | Cavity | 216 | 216 | 288 | 384 | 432 |

| Cooling Form | Cavity | 216 | 216 | 288 | 384 | 432 | |

| Size(LxWxH) | CM | 263X157X230 | 263X157X230 | 281X160X250 | 315X260X273 | 315X260X273 | |

| OTHER | Power supply (3-phase AC) | V/HZ | 380/50 | 380/50 | 380/50 | 380/50 | 380/50 |

| KW | 332 | 332 | 360 | 568 | 568 | ||

| Chilling Water | ℃ | 5~10 | 5~10 | 5~10 | 7~9 | 7~9 | |

| Mpa | 0.8 | 0.8 | 0.8 | 0.8 | 0.8 | ||

| L/Min | 900 | 900 | 1200 | 1200 | 1200 | ||

| Cooling Water | ℃ | <25 | <25 | <25 | <25 | <25 | |

| Mpa | 0.3 | 0.3 | 0.3 | 0.3 | 0.3 | ||

| L/Min | 300 | 300 | 300 | 300 | 300 | ||

| Compressed Air | Mpa | 0.7~0.9 | 0.7~0.9 | 0.7~0.9 | 0.7~0.9 | 0.7~0.9 | |

| L/Min | 800 | 800 | 1200 | 1200 | 1200 | ||

| Machine Size(LxWxH) | CM | 930X180X250 | 990X180X250 | 1090X205X260 | 1180x250X270 | 1240X270X300 | |

| Machine Weight | T | 26 | 28 | 34 | 39 | 44 | |

* Demark reserves the right to make changes to the products and specifications are subject to change without notice.