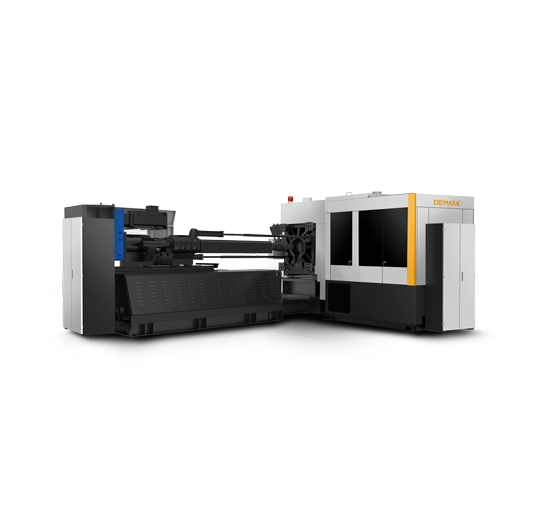

ECO PET Preform Injection Molding Machine

● For 24, 32, 48, 72 Cavities PET Preform Molds

● Cycle: 9.5S/14g

● Maintaining Pressure and Plasticization at the same time

● With 3 Station Cooling Robot, Electric Plasticization

● The low investment PET Preform Production Line / syetem

- 1.Independent electric screw drive brings you both plasticization and energy efficiency

- 2.Brand new BECKHOFF centrailized control system special designed for PET production.

- 3.Three station post cooling robot makes the preform perfectly cooled with better cycle time.

- 4.Advanced proportional valve control technology makes the fast and precise clamping possible.

- 5.The hydraulic system was driven by a servo motor whick ensure the lower energy consumption and sufficient hydraulic power supply.

- 6.With the advanced pressure hold technology ,the system makes the plasticization and pressure hold at the same time therefore has a better cycle time for production .

- 7.Special design for PET preform mould,which ensure the fast clamping movement and uniformly forced of the mould.

| Model | UNIT | ECO260/2000 | ECO300/3000 | ECO300/4300 | ECO400/4300 | |

| INJECTION UNIT | Screw L/D Ratio | L/D | 25 | 25 | 25 | 25 |

| Screw Diameter | mm | 80 | 90 | 100 | 100 | |

| Theoretical shot volume | cm3 | 1724 | 2456 | 3589 | 3589 | |

| Shot Weight(PET) | g | 2069 | 2947 | 4307 | 4307 | |

| Injection Pressure | kgf/cm2 | 1138 | 1210 | 1117 | 1117 | |

| Plasticizing capacity (PET) | g/s | 80 | 110 | 150 | 150 | |

| CLAMPING UNIT | Clamping Force | Ton | 260 | 300 | 300 | 400 |

| Clamping Stroke | mm | 540 | 585 | 585 | 670 | |

| Max/Min Thickness of Mould | mm | 200~580 | 300~720 | 300~720 | 300~820 | |

| Space Between Tie Bars(WxH) | mm | 570x570 | 660x760 | 660X760 | 845X845 | |

| Ejector Stroke | mm | 150 | 180 | 180 | 180 | |

| Ejector Force | Ton | 8 | 20 | 20 | 20 | |

| NO.of Ejector Pins | PCS | 5 | 9 | 9 | 13 | |

| Cavity(Max) | PCS | 32 | 48 | 48 | 72 | |

| MOULD | Neck of Bottle (max) | mm | 38 | 42 | 42 | 42 |

| Lengh of preform | mm | 160 | 190 | 190 | 220 | |

| Weight of Preform(Suggest) | g | 30 | 30 | 50 | 50 | |

| Type of Mould | Needle Valve Of Non-cutting PET Preform Mold | |||||

| POWER UNIT | Pump Motor Power | KW | 39+45 | 39+55 | 39+39+82 | 39+39+82 |

| Robot Power | KW | 12 | 36 | 36 | 43 | |

| Heater Input Capacity | KW | 43 | 51 | 63 | 63 | |

| Mould Heater Capacity | KW | 30 | 55 | 55 | 68 | |

| ROBOT | Cooling Tubes | Cavity | 96 | 144 | 144 | 216 |

| Cooling Form | Cavity | 32X3 | 48X3 | 48X3 | 72X3 | |

| Size(LxWxH) | CM | 257X160X220 | 280X160X250 | 280X160X250 | 310X160X250 | |

| OTHER | Power supply (3-phase AC) | V/HZ | 380/50 | 380/50 | 380/50 | 380/50 |

| KW | 169 | 236 | 314 | 334 | ||

| Chilling Water | ℃ | 5~12 | 5~12 | 5~12 | 5~12 | |

| Mpa | 0.8 | 0.8 | 0.8 | 0.8 | ||

| L/min | 700 | 900 | 900 | 1200 | ||

| Cooling Water | ℃ | <25 | <25 | <25 | <25 | |

| Mpa | 0.3 | 0.3 | 0.3 | 0.3 | ||

| L/min | 100 | 100 | 120 | 120 | ||

| Compressed Air | Mpa | 0.7~0.9 | 0.7~0.9 | 0.7~0.9 | 0.7~0.9 | |

| L/min | 400 | 800 | 800 | 1200 | ||

| Machine Size(LxWxH) | cm | 840X160X240 | 880X170X250 | 980X210X250 | 1020X210X250 | |

| Machine Weight | Ton | 14 | 18 | 19 | 24 | |

| Model | UNIT | ECO225P/2000 | ECO225P/3000 | ECO300P/4300 | ECO300P/5400 | |

| INJECTION UNIT | Screw L/D Ratio | L/D | 25 | 25 | 25 | 25 |

| Screw Diameter | mm | 80 | 90 | 100 | 110 | |

| Theoretical shot volume(max) | m | 1724 | 2456 | 3589 | 4481 | |

| Shot Weight(PET) | g | 2069 | 2947 | 4307 | 5377 | |

| injection pressure | kgf/cm2 | 1138 | 1210 | 1117 | 1111 | |

| Plasticizing capacity (PET) | g/s | 170 | 230 | 230 | 280 | |

| CLAMPING UNIT | Clamping Force | Ton | 225 | 225 | 300 | 300 |

| Clamping Stroke | mm | 550 | 550 | 600 | 600 | |

| Max/Min Thickness of Mould | mm | 450~720 | 450~720 | 500-800 | 500-800 | |

| Space Between Tie Bars(WxH) | mm | 620x725 | 620x725 | 780x780 | 780x780 | |

| Ejector Stroke | mm | 160 | 160 | 200 | 200 | |

| Ejector Force | Ton | 11.1+21.6 | 11.1+21.6 | 11.1+31.4 | 11.1+31.4 | |

| NO.of Ejector Pins | PCS | 17 | 17 | 9+4 | 9+4 | |

| Max.System pressure | kgf/ c㎡ | 175 | 175 | 175 | 175 | |

| MOULD | Cavity(Max) | PCS | 48 | 48 | 72 | 96 |

| Weight of preform | g | 50 | 50 | 40 | 40 | |

| Length of preform | mm | 200 | 200 | 220 | 220 | |

| neck of bottle (max) | mm | 38 | 38 | 38 | 30 | |

| Type of mould | Needle Valve Of Non-cutting PET Preform Mold | |||||

| POWER UNIT | Pump Motor Power | KW | 39+55 | 39+55 | 39+39+82 | 39+39+82 |

| Robot Power | KW | 36 | 36 | 36 | 43 | |

| Heater Input Capacity | KW | 51 | 51 | 63 | 63 | |

| Mould Heater Capacity | KW | 55 | 55 | 55 | 68 | |

| ROBOT | Cooling tubes | Cavity | 144 | 144 | 216 | 288 |

| Cooling Form | Cavity | 48X3 | 48X3 | 72X3 | 96X3 | |

| Size(LxWxH) | cm | 280X160X250 | 280X160X250 | 280X160X250 | 310X160X250 | |

| OTHER | Power supply (3-phase AC) | V/HZ | 380/50 | 380/50 | 380/50 | 380/50 |

| KW | 236 | 236 | 314 | 344 | ||

| Chilling Water | ℃ | 5~12 | 5~12 | 5~12 | 5~12 | |

| Mpa | 0.8 | 0.8 | 0.8 | 0.8 | ||

| L/min | 900 | 900 | 900 | 1200 | ||

| Cooling Water | ℃ | <25 | <25 | <25 | <25 | |

| Mpa | 0.3 | 0.3 | 0.3 | 0.3 | ||

| L/min | 120 | 120 | 120 | 300 | ||

| Compressed Air | Mpa | 0.7~0.9 | 0.7~0.9 | 0.7~0.9 | 0.7~0.9 | |

| L/min | 800 | 800 | 800 | 1200 | ||

| Machine Size(LxWxH) | cm | 880X170X250 | 880X170X250 | 980X210X250 | 1020X210X250 | |

| Machine Weight | Ton | 18 | 18 | 19 | 24 | |

* Demark reserves the right to make changes to the products and specifications are subject to change without notice.