| ITEMS |

UNIT |

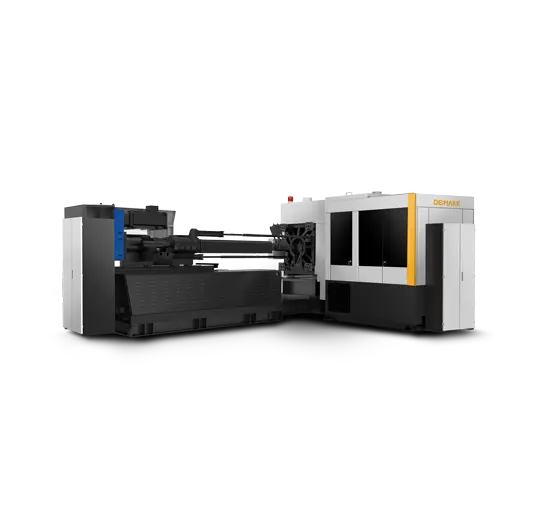

DMK-CM16 |

DMK-CM24 |

DMK-CM28 |

DMK-CM36 |

DMK-CM48 |

| Raw material |

|

PP/HDPE/LDPE/PTE |

PP/HDPE/LDPE/PTE |

PP/HDPE/LDPE/PTE |

PP/HDPE/LDPE/PTE |

PP/HDPE/LDPE/PTE |

| Max capacity |

pcs/hr |

9000-16000 |

17000-25000 |

19000-28000 |

22000-36000 |

33000-52000 |

| 3025 capacity |

pcs/hr |

16000 |

25000 |

28000 |

36000 |

52000 |

| 38mm capacity |

pcs/hr |

9000 |

17000 |

19000 |

22000 |

33000 |

| Diameter of cap |

mm |

22-42 |

22-42 |

22-42 |

22-42 |

22-42 |

| Height of cap |

mm |

10-25 |

10-25 |

10-25 |

10-25 |

10-25 |

| Number of cavity |

PCS |

16 |

24 |

28 |

36 |

48 |

| Actual power consumption |

KW |

16-20 |

28-33 |

32-35 |

32-42 |

50-60 |

| Operating pressure |

Mpa |

0.8 |

0.8 |

0.8 |

0.8 |

0.8 |

| Pressure consuming |

M3/hr |

2 |

2 |

2 |

2 |

2 |

| Power supply |

V/HZ |

380V/50HZ |

380V/50HZ |

380V/50HZ |

380V/50HZ |

380V/50HZ |

| Machine weight |

TON |

4.5 |

6.3 |

6.5 |

8 |

11.5 |

| Dimension |

mm |

4300*1750*2600 |

4800*2180*2600 |

4800*2180*2600 |

5300*2180*2600 |

6100*2180*2600 |

| Installation power |

KW |

40 |

55 |

55 |

95 |

75 |

|

|

|

|

|

|

|

* Demark reserves the right to make changes to the products and specifications are subject to change without notice.